Materials and products

METLAC GROUP manufactures more than 50.000 tons of coatings per year. However, METLAC’s production capacity is much higher than the current demand. This is due to the high level of investment made to cover medium to long term needs.

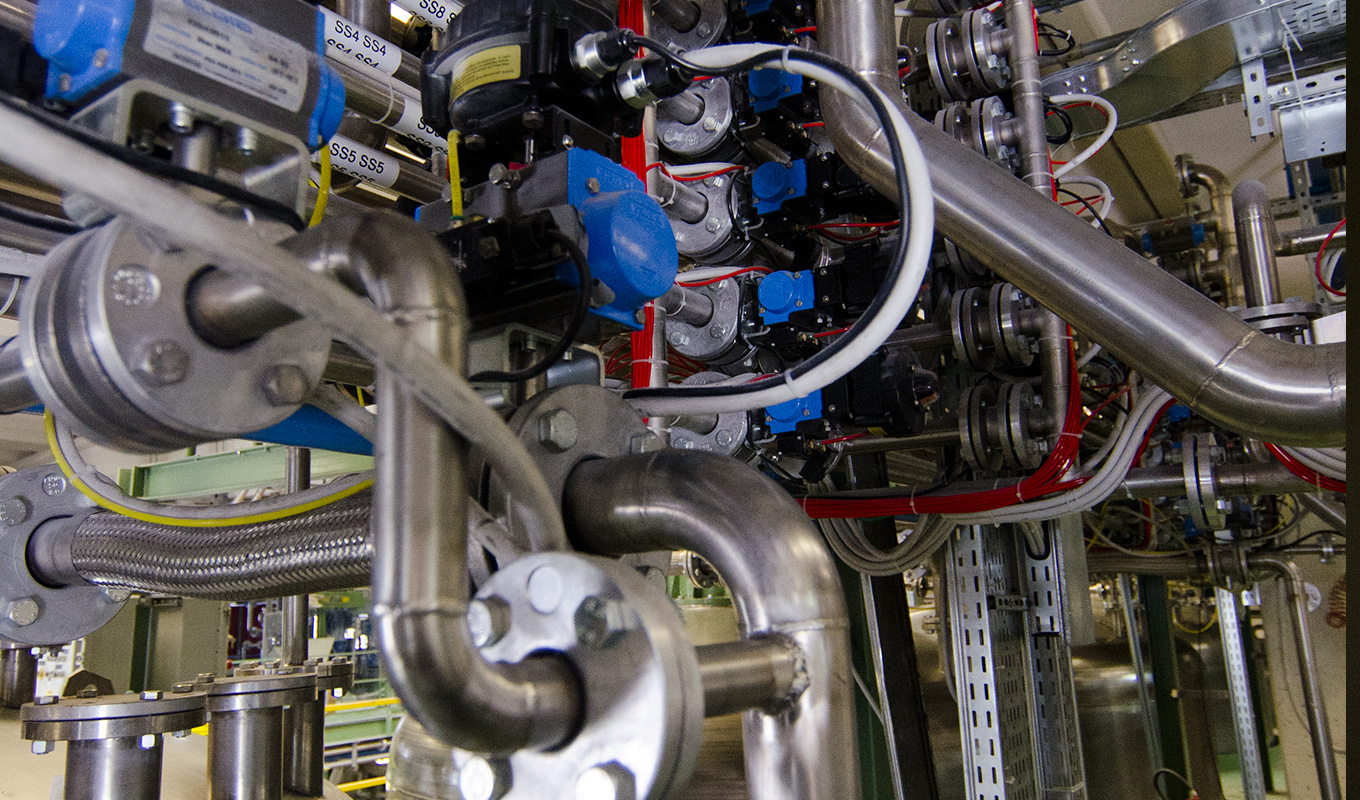

All of METLAC’s manufacturing processes are authorized and controlled during each stage of the procedure by employing a completely automated system, which eliminates any possibility of human error.

Machinery and associated equipment are dedicated by product type. METLAC uses the “poka-yoke” system of identification in order to avoid contamination.

All raw materials and finished products are tested before use and the high quantity of raw material stocks guarantees flexibility and efficiency in customer service.

The automated warehouse, which contains 10,000 pallet-size spaces, ensures ideal stock conditions for raw materials, intermediates and finished products and, by means of the new RFID labelling system, guarantees full traceability of all finished products and raw materials.

The Company also has some 60 stainless-steel vessels with sizes from 50 to 60 m3 and with stirring and temperature control systems to stock raw materials and finished products.